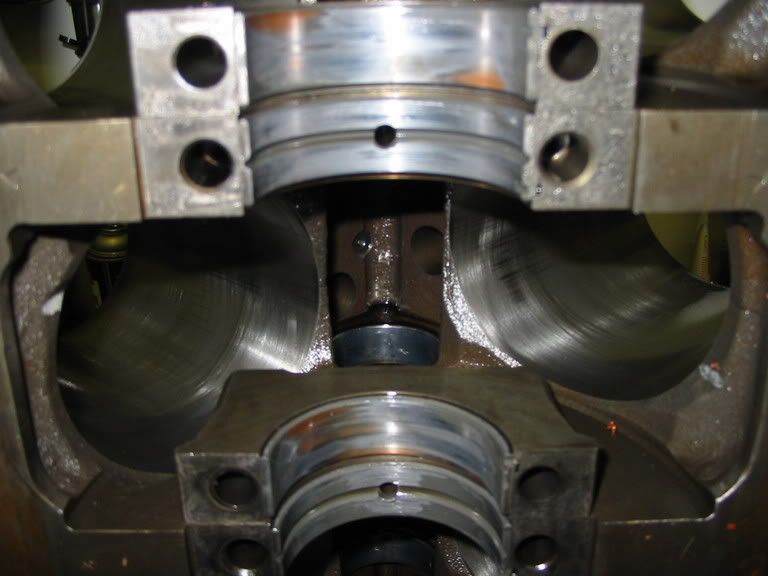

This block came in the engine shop today and the customer wanted to know why the bearings were tore up and once I pointed out that the center caps were flexing and pinching the bearings that why the copper was showing on the sides of the bearings and the crank was in bad shape and needs to be turned as well.

Notice the registers and how they are fretted and the metal transfer from cap to block as this was a 400 horse 2 barrel circle track engine and this engine was balanced and the pistons show no signs of detonatoin.

This guy read in a magazine that 2 bolt blocks were good for 450 horse and now he has a little different opinion on this. I told him thats why a 2 bolt 400 block have wider center main caps as this helps keep the cap more stable in the register.

Now we will put center splayed caps on this block and I am sure next year the bearing won't look like this.

![Image]()

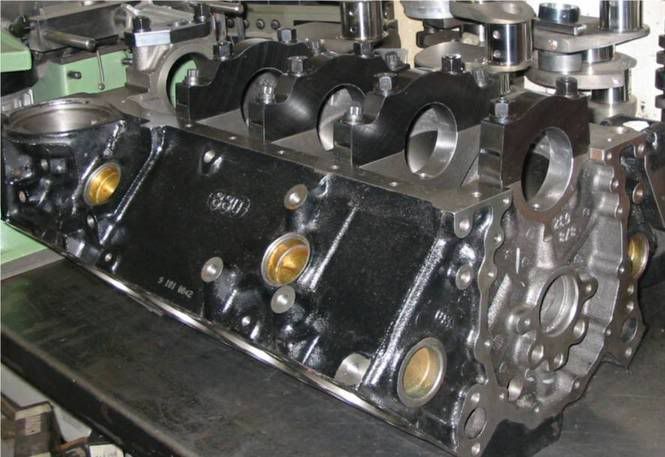

Notice the registers and how they are fretted and the metal transfer from cap to block as this was a 400 horse 2 barrel circle track engine and this engine was balanced and the pistons show no signs of detonatoin.

This guy read in a magazine that 2 bolt blocks were good for 450 horse and now he has a little different opinion on this. I told him thats why a 2 bolt 400 block have wider center main caps as this helps keep the cap more stable in the register.

Now we will put center splayed caps on this block and I am sure next year the bearing won't look like this.